(Thermal, Nuclear, Hydro)

Service & Repair

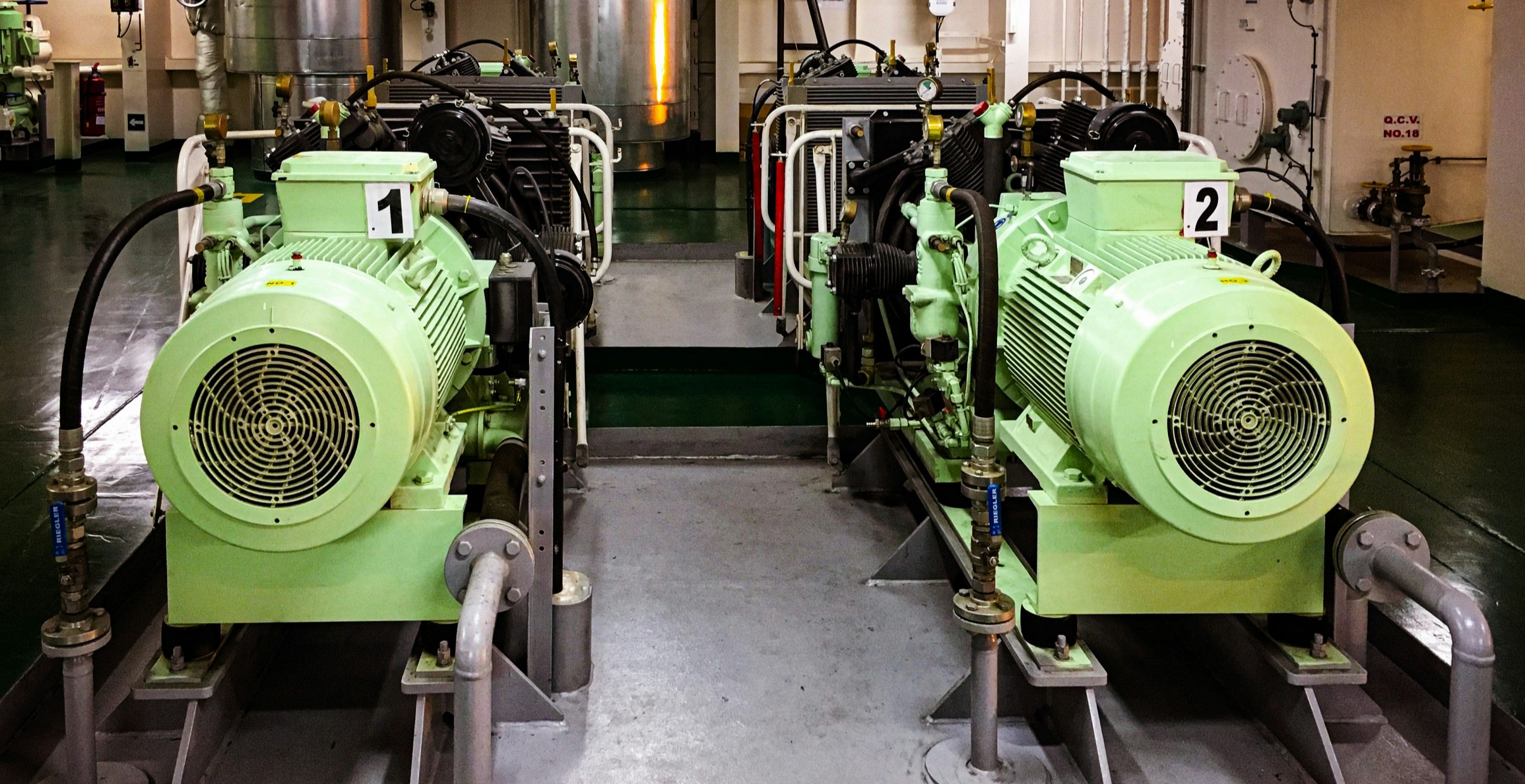

The petrochemical industry is a pillar of China’s economy. Sinopec and other majors operate some of the world’s largest refineries and chemical complexes—facilities whose safe, uninterrupted performance depends on rigorous, round-the-clock maintenance and inspection of highly complex machinery. Even a single unplanned shutdown can trigger enormous financial losses and serious safety risks.

Modern inspection instruments and predictive-maintenance solutions are therefore indispensable tools for keeping these high-value plants running safely and efficiently.

JRONT Instruments for Critical Equipment

Motors (AC/DC), permanent-magnet machines, traction motors, pumps

Portable bolt inspection & analysis systems for preload testing of any bolted joint

Electrical equipment

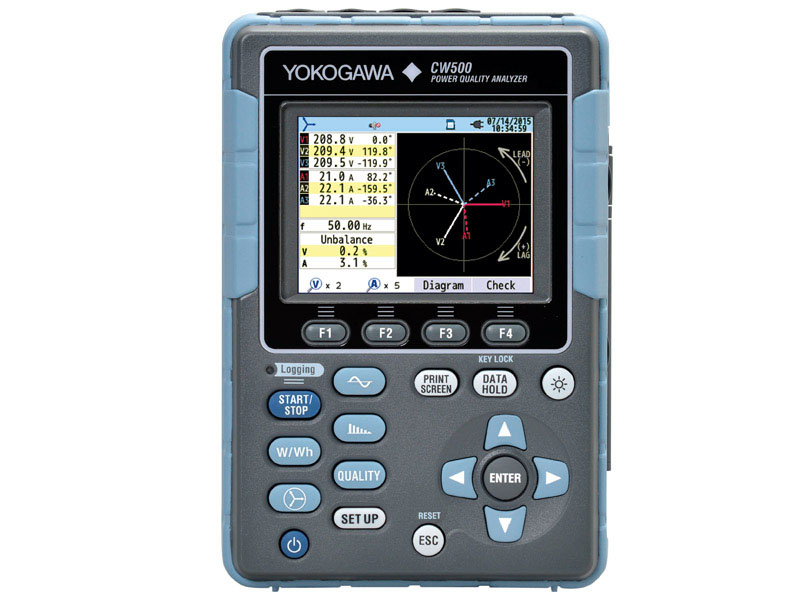

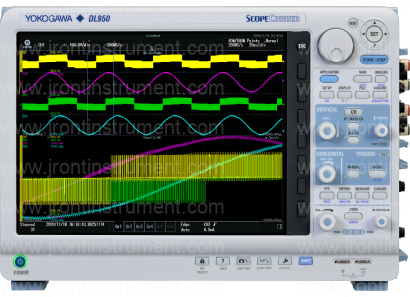

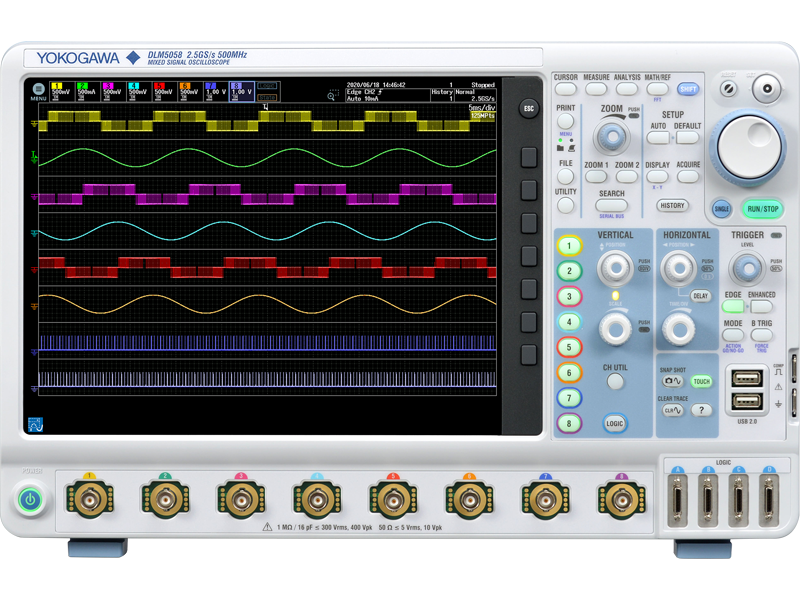

Key assets such as motor systems are diagnosed with the static motor & winding analyser ITIG IV. Electrical equipment is monitored with the DL950 ScopeCorder, high-performance WT1800 Power Analyser, or CW500 Power Quality Analyser. Bolted joints are checked with our bolt-testing systems. Petrochemical environments demand explosion-proof instruments; we supply intrinsically safe multimeters for use in refineries and other hazardous areas.

For further information or inquiries, please feel free to contact us at any time

Driven by accelerated power-sector reform and continuously optimized investment structures, China is building a clean, low-carbon, safe and efficient modern energy system. Power-plant equipment is becoming ever more complex, encompassing generation and transmission assets such as boilers, steam turbines, gas turbines, hydro turbines, generators and transformers. Because these systems are tightly interlinked, a single equipment failure can halt production and cause enormous economic losses.

Proactive maintenance is therefore essential to ensure safe, economical and stable power-system operation.

Modern Inspection Instruments & Solutions for Power-Generation Maintenance

JRONT instruments are applied to the following equipment:

Wind: generators, gearboxes, hydro turbines

Thermal: electrical equipment, steam turbines, generators, condensate pumps, circulating pumps

Nuclear: turbo-generator sets, generators, main feed-water pumps, fuel-transfer systems, condensate pumps, main transformers and circulating pumps

For further information or inquiries, please feel free to contact us at any time

— we are always happy to provide assistance.

Contact us: +86(10)83659992、13901388706、13910312910

Motor manufacturers use the iTIG Static Motor & Winding Analyser for outgoing quality control, giving you and your customers complete confidence.

Service and repair shops rely on iTIG for maintenance, overhaul and rewind operations—preventing unplanned downtime and controlling operating costs.

Motor and generator failures can occur without warning. iTIG enables data-driven decisions on in-service assets, detecting insulation weaknesses before it’s too late.

For further information or inquiries, please feel free to contact us at any time

— we are always happy to provide assistance.

Contact us: +86(10)83659992、13901388706、13910312910

Paper making converts plant fibres into pulp through mechanical, chemical or combined processes, then forms paper products by evenly blending pulp and additives—either manually or on high-speed machines.

Driven by China’s “dual-carbon” goals, the pulp & paper sector is rapidly upgrading toward cleaner, greener and more intelligent production. Mills now demand continuous, high-efficiency operation to maximise profit.

JRONT’s iTIG Static Motor & Winding Analyser supports motor reliability programmes in paper plants, preventing unplanned shutdowns and controlling operating costs. Motor and generator failures can occur without warning; iTIG delivers the data-driven insights maintenance teams need to act before problems escalate.

For further information or inquiries, please feel free to contact us at any time

— we are always happy to provide assistance.

Contact us: +86(10)83659992、13901388706、13910312910

Why Motor Maintenance Is Critical

In mining and mineral processing—as in virtually every other industrial operation—electric motors are at the heart of the process.

They power generators, pumps, crushers, mills, hoists and other essential equipment. Because these motors operate under harsh conditions and must meet high production demands, they must be properly designed, built and maintained to ensure durability and long service life; otherwise they will fail prematurely.

Motor Maintenance: Essential for Mining's Continuous Success

Any production halt in mining translates into lost revenue, and when a motor failure drives weeks of downtime, that loss compounds. Losing a single large machine can disrupt the entire operation. Mining motor maintenance—preventive servicing, load testing and winding inspections—delivers vital health data while boosting the reliability and service life of every motor-driven asset.

Our proven test equipment extends motor life and performance, helping mining operations avoid revenue loss from unplanned shutdowns. Contact us today for a quotation or to schedule service.

For further information or inquiries, please feel free to contact us at any time

— we are always happy to provide assistance.

Contact us: +86(10)83659992、13901388706、13910312910

ENGLISH

ENGLISH