Operations & Maintenance

Value to Service and

Retrofit Operations

Wind Turbine Motor Pre-Maintenance Inspection Service

Finding the right balance between minimising downtime and controlling operating costs is a constant challenge for O&M teams. If minimising unplanned outages through robust maintenance and motor-reliability programmes is your top priority—just as it is for many of our clients—JRONT can help make those programmes simpler and more effective.

We deliver motor-testing services tailored to each customer’s needs, issue detailed test reports, and use trending data to help identify faults before they escalate.

Our instruments automatically track test data over time—including partial discharge (PD)—for every motor and generator. Results can be viewed in Microsoft Excel or analysed with database software for trend evaluation.

Need rapid answers when problems occur? Contact us!

* Troubleshooting & Diagnostics: Fast, targeted diagnostics pinpoint root causes, reducing fault-finding time.

Predictive Maintenance for Wind Operations: Trending data highlights insulation weaknesses before they become critical, enabling wind-farm operators to schedule turbine maintenance proactively and avoid unplanned shutdowns.

Service Advantages * Exclusive agency for all motor-testing equipment used * On-site, certified test engineers * Comprehensive test reports and root-cause analysis support Compliance Standards Surge-test voltage requirements according to: * ANSI/EASA AR100-2015 * IEEE 522-2004 * IEC 60034-15:2009 (3.0) |

|

For further information or inquiries, please feel free to contact us at any time

— we are always happy to provide assistance.

Contact us: +86(10)83659992、13901388706、13910312910

Portable Bolt-Check & Analysis System

Our bolt-inspection team is dedicated to making wind-turbine and other critical bolted joints more reliable.

By delivering precise preload data and full traceability for every bolt, our reports enable you to schedule service and maintenance that prevents fatigue failure and loosening caused by vibration.

Service Advantages: * Real-time data captured on site * Proprietary, regularly calibrated and maintained equipment * Customised testing programmes to suit every project * Reduced bolt-maintenance cycles |

|

For further information or inquiries, please feel free to contact us at any time

— we are always happy to provide assistance.

Contact us: +86(10)83659992、13901388706、13910312910

Wind Energy

After more than a decade of rapid growth, China's wind sector has shifted from sheer capacity expansion to higher quality and lower cost. The next frontier is offshore deep-water projects, where the O&M market is poised for sustained growth and surging demand.

Intelligent O&M technologies and smart equipment are already being deployed in new offshore wind farms.

Modern JRONT measurement products serve the wind industry by monitoring:

generators, gearboxes, tower bases, platforms, and electrical diagnostics.

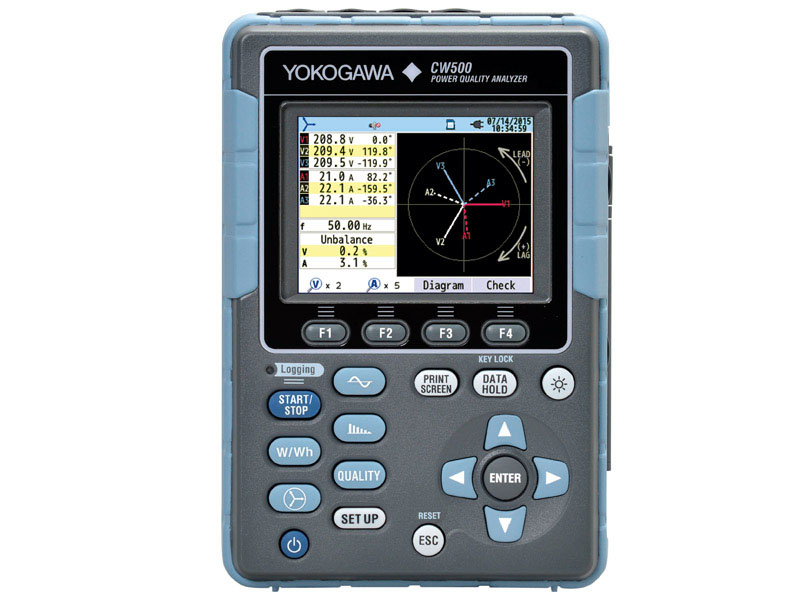

Predictive maintenance uses data-centric high-voltage tests—surge, partial discharge (PD) and more—with the iTIG static motor tester and winding analyser. Consistent trending data lets operators spot insulation weaknesses before they become critical, enabling planned repairs instead of unplanned shutdowns.

The portable bolt-preload & analysis system is widely used on wind and hydro turbines for real-time monitoring of bolt tension, loosening and breakage; it also covers steel structures, bridges and flanged joints, ensuring critical bolts remain secure and preventing catastrophic failures.

Recommended Products & Services

Services:

1. Helideck surface friction-coefficient testing

2. Helideck inspections, safety-net inspections, refuelling-system checks and full CAP 437 compliant test reports

3. Bolt-preload testing services

4. Wire-rope non-destructive testing

5. Helideck friction-tester rental

6. Custom maintenance & inspection programmes aligned with Industry 4.0

For further information or inquiries, please feel free to contact us at any time

— we are always happy to provide assistance.

Contact us: +86(10)83659992、13901388706、13910312910

How Bolt-Check Adds Value to Service and Retrofit Operations

Whether you want to extend wind-turbine life or streamline service workflows, Bolt-Check supplies the tools to complete every job confidently, accurately and with fully traceable documentation.

* Identifies only the bolts that actually need attention

* Speeds up maintenance so technicians can focus on what matters

* Records data automatically—no manual note-taking required

* Reduces human error and guarantees reliable records

* Enables data-driven service planning and fewer site visits

* Condition-based bolt data help support life-extension decisions

* In the Faroe Islands case, Bolt-Check cut related maintenance costs by ~75% (source: owner’s internal report; results elsewhere may vary)

Servicing wind turbines in the Faroe Islands presents unique logistical challenges.

Heavy equipment, unpredictable weather, and remote locations make bolt tension verification time-consuming and costly. However, by integrating Bolt-Check into a maintenance routine, Mr. Eyðfinnur Lenvig has significantly reduced both time and expenses while improving the accuracy of bolt inspections.

Wind turbine foundations require periodic bolt tension checks to ensure structural integrity. Traditionally, this process required hydraulic tensioning equipment that was both heavy and difficult to transport. “Originally, the bolts were tensioned using a jack that was so heavy it needed a crane just to move it,” explains Lenvig.

When the wind farm owner needed the bolts inspected after one year, Lenvig explored alternatives. “My son, who was studying at the University of Southern Denmark at the time, introduced me to Bolt-Check after hearing about it from one of his professors,” he says. This led to a discussion with R&D Test Systems, where Lenvig learned how ultrasonic measurement could streamline the process. “After a meeting with your specialists, I presented the solution to the wind farm owner, who was interested in testing it.”

The transition to Bolt-Check began with a comparative study. “We initially tested all the bolts using the hydraulic jack and then recorded the data with Bolt-Check,” Lenvig recalls. “On one turbine, we even fully loosened each bolt one at a time to establish a reference point.” By the second year of inspections, Bolt-Check became the primary tool, eliminating the need for hydraulic equipment altogether.

Significant time and cost savings

Using Bolt-Check has led to a drastic reduction in maintenance time. “With your system, the entire process can be done in a single day by one person,” says Lenvig. “Had we continued using the hydraulic equipment, we would have only been able to test every tenth bolt, and the process would have taken at least three days.”

The cost benefits are equally compelling. “Expenses for the wind farm owner have decreased by about 75% or more,” he notes. Previously, inspections required expensive equipment rental, transportation, and additional personnel. “With the old system, we needed an electric generator, a hydraulic station, a jack, an extra technician, and a crane truck just to handle the equipment. Plus, we needed a transport vehicle for storage, as the equipment couldn’t be left on-site overnight without supervision.”

Data-driven maintenance for long-term reliability

Beyond saving time and costs, Bolt-Check provides a critical advantage: long-term data tracking. “We can now measure and document exactly how much tension the bolts lose each year,” says Lenvig. “This wasn’t possible with the hydraulic jack.”

This data-driven approach enhances predictive maintenance, helping wind farm operators ensure that bolts remain within the correct tension range, improving overall turbine reliability and lifespan.

Expanding the potential of Bolt-Check

Given its success in wind turbine maintenance, Lenvig believes Bolt-Check has applications beyond the renewable energy sector. “Any large bolts requiring precise tensioning should be checked with ultrasonic measurement,” he suggests. “It increases bolt lifespan and ensures consistent, correct tensioning.”

As Mr. Eyðfinnur Lenvig will continue to promote efficient maintenance solutions in the Faroe Islands, Bolt-Check has become an invaluable tool in their service operations. With its ability to replace cumbersome hydraulic systems, reduce costs, and provide precise data, Bolt-Check sets a new standard for bolt inspection in the wind industry and beyond.

For further information or inquiries, please feel free to contact us at any time

— we are always happy to provide assistance.

Contact us: +86(10)83659992、13901388706、13910312910

ENGLISH

ENGLISH